The PVC pansi calendering njira ndi kothandiza ndi mosalekeza kupanga ndondomeko, amene makamaka oyenera kupanga homogeneous ndi permeable kapangidwe mapepala (monga malonda homogeneous permeable pansi). Cholinga chake ndikupangira pulasitiki ya PVC yosungunuka kukhala yopyapyala yopyapyala kudzera mu kalendala yamitundu yambiri, kenako ndikuziziritsa kuti iwoneke. Zotsatirazi ndi masitepe enieni komanso mfundo zazikuluzikulu zaukadaulo:

I. Kalendala

Kusanganikirana kotentha kwambiri, kuzizira ndi kuzizira, kusakaniza kwamkati ndi kupanga pulasitiki, kusakaniza kotseguka ndi kudyetsa.

Calendering ya ma roll anayi, embossing/laminating, kuziziritsa ndi kupanga, kudula ndi mapindikidwe

II. Mfundo zazikuluzikulu zogwirira ntchito pang'onopang'ono ndi magawo aukadaulo

1. Yaiwisi Zinthu Pretreatment ndi Kusakaniza

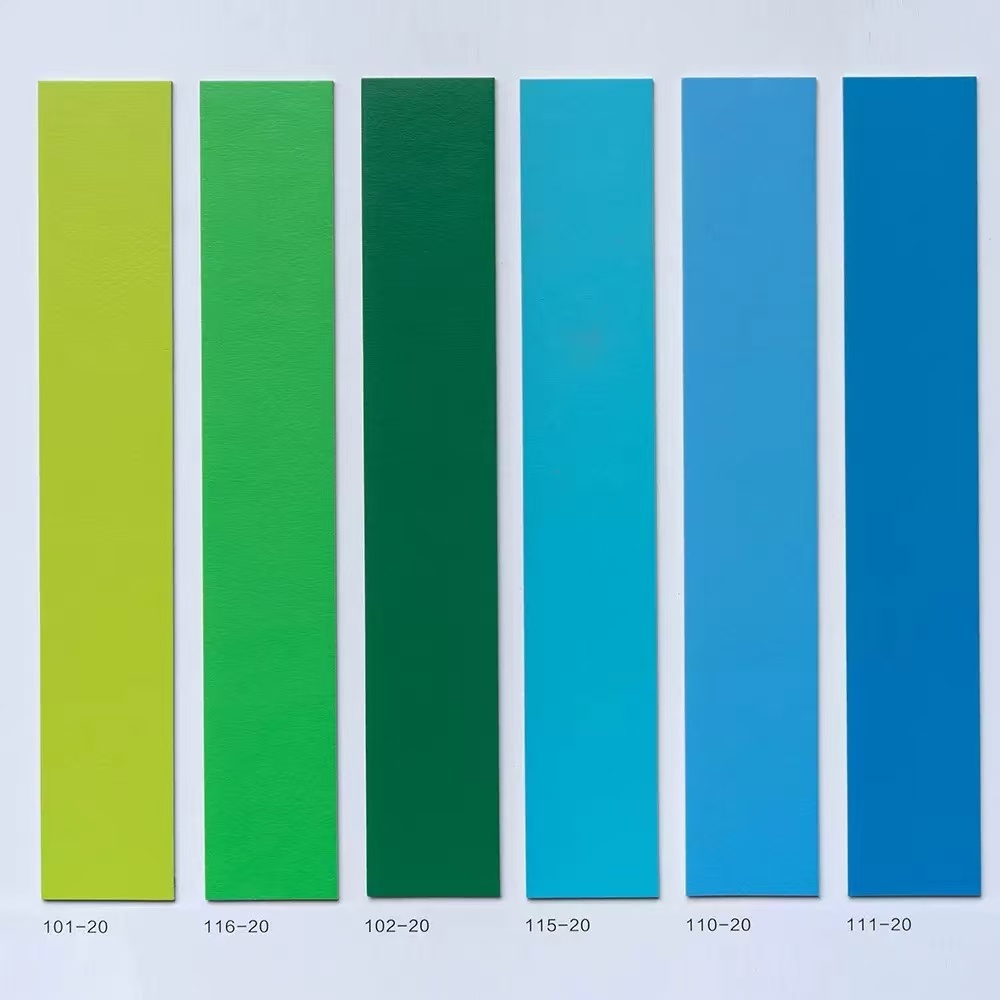

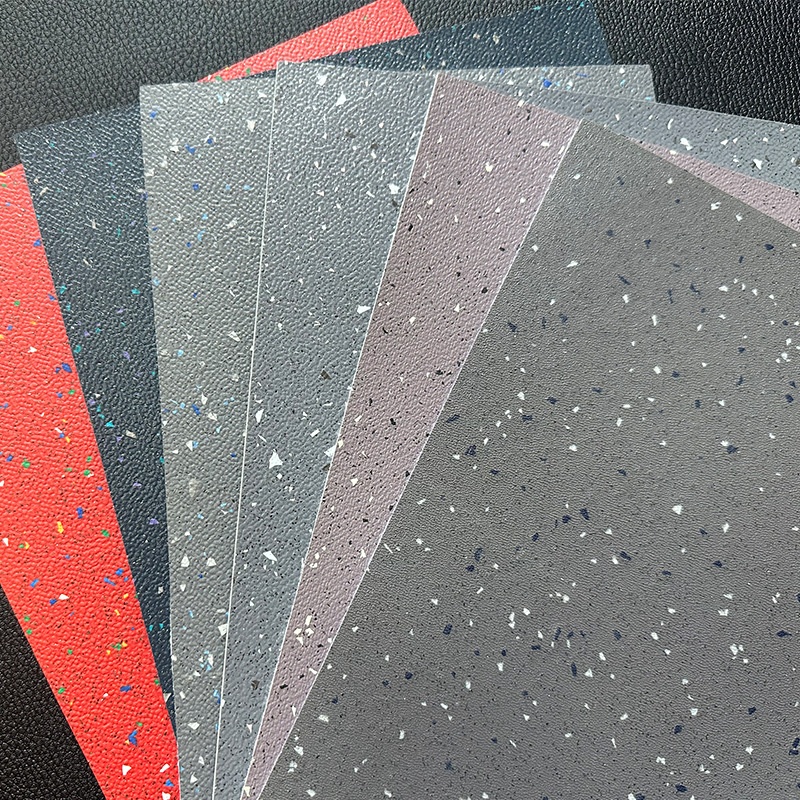

Mapangidwe a Chilinganizo (Chitsanzo): - PVC utomoni (S-70 mtundu) 100 mbali, - Plasticizer (DINP / chilengedwe ochezeka ester) 40-60 mbali, - Calcium carbonate filler (1250 mauna) 50-80 mbali, - Kutentha stabilizer (calcium zinc composite, 5-5 mbali ya lubricant) - 5-1 gawo la lubricant - Pigment (titanium dioxide / ufa wamtundu wa inorganic) magawo 2-10

Njira Yosakaniza *:

Kusakaniza kotentha: Chosakaniza chothamanga kwambiri (≥1000 rpm), kutentha kwa 120 ° C (10-15 mphindi) kuti PVC itenge pulasitiki; Kusakaniza Kozizira: Kuzizira mofulumira mpaka pansi pa 40 ° C (kuteteza zotupa), nthawi yosakaniza yozizira ≤ Mphindi 8.

2. Pulasitiki ndi Kudyetsa

- Wosakaniza Wamkati: Kutentha 160-170 ° C, Kupanikizika 12-15 MPa, Nthawi 4-6 Mphindi → Kupanga mphira wofanana;

Tsegulani chosakanizira: Kutentha kwa twin-roll 165±5°C, Roller Gap 3-5 mm → Dulani mizere kuti mupitirize kudya ku kalendala.

3. Ma Calendar odzigudubuza anayi (Core Process)

-Njira Zofunika:

- Roller Speed Ratio: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (kuletsa kudzikundikira zinthu);

- Kulipiridwa Kwapakati-Kutalika: Roller 2 idapangidwa ndi korona wa 0.02-0.05mm kuti ithetse kupindika kwamatenthedwe. 4. Pamwamba Chithandizo ndi Lamination

Embossing: Embossing roller (silicone / zitsulo) kutentha 140-150 ° C, kuthamanga 0.5-1.0 MPa, liwiro lofanana ndi mzere wa kalendala;

Kuyika kwa gawo lapansi (Mwasankha): Nsalu yagalasi ya fiber / yosalukidwa, yotenthedwa ndi preheated (100 ° C), imakhala yonyezimira ndi PVC yosungunuka pa chogudubuza #3 kuti ipititse patsogolo kukhazikika kwa dimensional.

5. Kuzizira ndi Kujambula

Kutentha kozizira kwa magawo atatu:

Kuwongolera Kupanikizika: Kuthamanga kwa mafunde 10-15 N/mm² (kupewa kuzizira kozizira ndi kupunduka).

6. Kudula ndi Kupiringa

- Kuyeza kwa makulidwe a Laser pa intaneti: Ndemanga zenizeni zenizeni zimasintha kusiyana kwa roller (kulondola ± 0.01mm);

- Kudulira Mokha: M'lifupi mwake zidutswa ≤ 20mm, zobwezerezedwanso ndikupangidwanso kuti zigwiritsidwenso ntchito;

- Mapiritsi: Kumangirira kosalekeza pakati, mpukutu m'mimba mwake Φ800-1200mm. III. Zovuta za Njira ndi Zothetsera

1. Makulidwe Osafanana. Choyambitsa: Kutentha kwa Roller Kusinthasintha > ±2°C. Yankho: Kutsekedwa-Loop Thermal Temperature Control + Close-Drilled Roller Cooling.

2. Gasi Pamwamba. Chifukwa: Kusakwanira Kusakaniza Kuchotsa Gasi. Yankho: Vutani Chosakaniza Chamkati (-0.08 MPa).

3. Mphepete Ming'alu. Chifukwa: Kuzizira Kwambiri / Kupanikizika Kwambiri. Yankho: Chepetsani Kuzizira Kwambiri Kumapeto Kutsogolo ndikuwonjezera Malo Ozizirira Pang'onopang'ono.

4. Chitsanzo Imfa. Chifukwa: Kusakwanira kwa Embossing Roller Pressure. Yankho: Wonjezerani Kuthamanga kwa Hydraulic ku 1.2 MPa ndikuyeretsani Pamwamba pa Roller.

IV. Njira Zosamalidwa Pachilengedwe komanso Zopititsa patsogolo Ntchito

1. Kusintha Kokhazikika Kwaulere Kwaulere:

- Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Idutsa Mayeso a EN 14372 Migration;

2. Pulasitiki Wosunga zachilengedwe:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Imachepetsa Kuopsa kwa Ecotoxicity.

3. Kubwezeretsanso Zinyalala:

- Zing'onozing'ono → Kusakaniza ndi zinthu zatsopano pa chiŵerengero cha ≤30% → Zogwiritsidwa ntchito popanga zosanjikiza.

V. Calendar vs. Extrusion (Kuyerekeza kwa Ntchito)

Kapangidwe kazogulitsa: Zomangamanga zokhala ndi perforated pansi/Zophatikiza zingapo zosanjikiza, Multilayer co-extrusion (wosanjikiza wosavala + wosanjikiza thovu)

Makulidwe osiyanasiyana: 1.5-4.0mm (Kulondola ± 0.1mm), 3.0-8.0mm (Kulondola ± 0.3mm)

Pamapeto Pamwamba: Kunyezimira kwakukulu/Kukongoletsa bwino (kutengera njere zamatabwa), Maonekedwe a Matte/Moyipa

Ntchito Zodziwikiratu: Zoyala pansi zokhazikika m'zipatala ndi malo opangira ma labotale, SPC yotsekera pansi panyumba

Chidule cha nkhaniyi: Phindu lalikulu la njira yosungiramo kalendala yagona mu "kulondola kwambiri" ndi "kusasinthika kwakukulu"

- Ubwino Wantchito:

- Kuwongolera kutentha kwa wodzigudubuza → makulidwe amitundu yosiyanasiyana <1.5%;

- Kujambula pamizere ndi kupukuta → Kukwaniritsa zowoneka ndi miyala / zitsulo;

- Zogwiritsidwa Ntchito:

Homogeneous perforated PVC yazokonza pansi ndi mkulu dimensional bata zofunika (monga Tarkett Omnisports mndandanda);

- Zowonjezera Zosintha:

- Kuwongolera Mwanzeru: Kusintha kwa gap kwa AI-powered dynamic roller (mayankho a makulidwe enieni);

- Kubwezeretsanso Mphamvu: Kutentha kwa zinyalala zamadzi zoziziritsa kumagwiritsidwa ntchito potenthetsera zinthu zopangira (kupulumutsa mphamvu 30%).

> Zindikirani: Pakupanga kwenikweni, kutentha kwa calendering ndi liwiro la roller ziyenera kusinthidwa molingana ndi formula fluidity ( melt index MFI = 3-8g / 10min) kuti asawonongeke (yellowing index ΔYI <2).

Nthawi yotumiza: Jul-30-2025